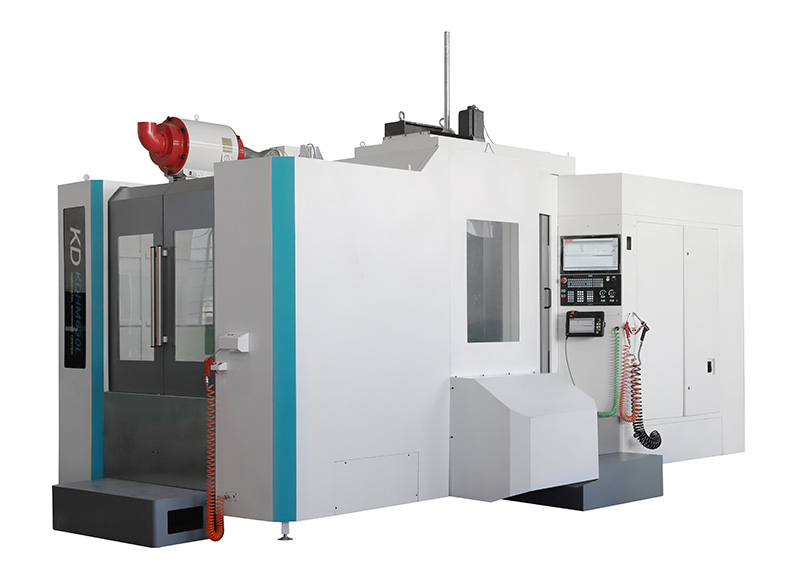

5-axis linked system such as FANUC, SIMENS is adopted to support the characteristics of high speed;high precision, rapid and stable feed.

It can support the expansion of functions such as the fourth axis, right-angle milling head, universal head, and gear head.

The casting is made of resin sand, which is made through natural aging and artificial aging twice.

The ball screw is pre-tensioned; it is suitable for heavy cutting and also suitable for precision machining.

The CNC system adopted has complete functions and reliable performance; the integrated design of electromechanical and hydraulic has compact structure.

Compact vertical structure design. Rigid spindle bearing structure ensures machines' heavy cutting.

The surface of the bedways is supersonic frequency hardened and precision ground with a long service life.

Precision ground and supersonic frequency hardened bed ways.

X, Y, and Z axes can optionally be equipped with linear grating scales to form a fully closed loop control system.

Both left and right are equipped with spindle holder. Synchronous drive of left and right spindle holder.